LT 2.4 Petrol engine to 2.5 TDI conversion

Printed From: The Brick-yard

Category: LT, Crafter & Sprinter Section

Forum Name: LT, Crafter & Sprinter Tech

Forum Description: All LT, Crafter & Sprinter tech related stuff in here

URL: http://www.brick-yard.co.uk/forum/forum_posts.asp?TID=60315

Printed Date: 19 Apr 24 at 18:11

Software Version: Web Wiz Forums 12.06 - https://www.webwizforums.com

Topic: LT 2.4 Petrol engine to 2.5 TDI conversion

Posted By: cnycl

Subject: LT 2.4 Petrol engine to 2.5 TDI conversion

Date Posted: 05 Dec 10 at 22:06

|

Finally our TDI conversion started progressing and I'll post it here step by step as my syncro friends (www.syncroturk.org) complete each level (wiring, sump modification, exhaust fitment, electrics, engine installation etc.). I hope this may help others deciding the same upgrade since we know this has been done before but there's no clear guide on how to do it properly.

As usual, disclaimer conditions apply; this conversion is something we're doing on our own risk and we can't guarantee it will function properly on your vehicle or you can get legal permits for road use and it is not approved by the vehicle manufacturer. Therefore if you're thinking of doing the same conversion, don't forget you'll be doing it on your own risk, knowing the conditions mentioned above.

Anyway the vehicle we're working on is an '88 VW LT 31 with 2.4l carbed petrol engine mated to a 5 speed gearbox. Donor vehicle is an Audi A6 with 5 pot 2.5l TDI engine.

This is the beginning, engine and wiring loom as they come from the breakers.

Wiring loom sorted and simplified.

2.4l turbo diesel LT sump and TDI sump side by side. Engine bracket on LT requires LT specific sump to be used on TDI engine since TDI sump is much deeper than the LT one. Bolt pattern of these sumps are very very smiliar except 2.4l sump is a little longer (1 pot) than 2.5 TDI.

Long portion to be cut is marked as below

And there it goes

Cut but unwelded part on the engine. Since depth is not uniform along the sump minor leveling is required before welding.

LT sump on TDI engine. We did not modifiy the oil pick up pipe yet.

Another angle

More to come as the project keeps going...

|

Replies:

Posted By: GT500

Date Posted: 06 Dec 10 at 09:34

|

Great stuff!!!! Just stripping my A6 at the mo! Try to catch up with ya! Wiring, is a pain. been stripping my loom back (its still in the car) testing as I go. Seems the immobiliser is a bit cleverer than I thought. Trying to find the current flow diagram for it... Anyway it did run lovley now it its stopped by the dammed immo. I have vagcom and all you get is "start blocked" Going to get the engine out today and sort it when its in the van. ANy chance we can have a detailed few pics of your loom please? Rob ------------- Rob... The only LT on 18" wheels. |

Posted By: Bo_Hedin

Date Posted: 10 Dec 10 at 20:00

|

Wow, Just what we've all been waiting to see. Good luck! Starting to think along these lines as I can't even get an oil filter for my engine anymore....and that extra performance would be great. ------------- VW LT28 2.4D Westfalia Sven Hedin 1978 |

Posted By: Canada LT28

Date Posted: 11 Dec 10 at 22:52

|

Excellent work Cnycl, I've got my 99 TDI 1.9 and am looking to go with the mech TDI pump to do away with the electronics. Looks like you will be done long before I actually get started. Mike |

Posted By: mechano

Date Posted: 12 Dec 10 at 19:10

|

Hi All, This is Eren, I am actually a syncronaut and not an LT fan, but as Cnycl stated this conversion is done in my garage and mainly by me. So here is what we did this weekend with Can (cnycl): Took out the engine from the LT (what a pain in the a..) also the transmission. with both engines out, we were able to see what will or will not fit. -The bellhousing pattern is same as TDI as expected, I am planning to use the TDI flywheel, pressure plate & starter, as the TDI has much more torque. -TDI has a 240mm clutch whereas the 6cyl petrol has 228mm, TDI also has a dual-mass flywheel. -TDI friction disc has the same spline as the 6cyl petrol so it can be used -The pilot bearing in the TDI flywheel is smaller and 6cyl petrol engine has a bearing pushed into the crankshaft with a bigger inside diameter. I was able to push out the bearing of the TDI flywheel, so installing a new bearing in to the TDI crankshaft will solve the problem. -However there is problem: When assembled, the TDI pressure plate will sit approximately 1cm out than the 6cyl petrol one. This means that the throw-out bearing will be pushed 1cm in to the transmission. I guess the clutch adjustment will not be enough to solve this problem, so I am planning to modify the lever of the clutch or may be its fulcrum or use another pressure plate... Looking at the other sides of engines: -The engine mounts are completely different, 6cyl ones wont fit to TDI, both sides need to be build from scratch. -The crankshaft pulley also the visco fan of the 6cyl petrol will fit to TDI engine. -The LT power steering pump fits to TDI engine with very little grinding of its bracket. -The alternator will not fit as it simply hits the turbo, has to be relocated and looks like a bit hard to find a new place... As for the wiring I have not finished it yet, as Can (cnycl) sent the pictures I have simplified it but I have to take out the wiring of the pedals from the main harness. I am not worried about the wiring as I have converted my syncro to TDI before (1.9 AFN engine) A syncro friend I met in Germany in syncro25yrs event sent the wiring diagram of this engine, here is the link: http://www.audifans.net/ftopict-33526-aat.html+wiring - http://www.audifans.net/ftopict-33526-aat.html+wiring http://www.audifans.net/ftopict-33526-aat.html+wiring - Here we are pulling the engine-less LT away from the garage with my syncro, we had some nice snow this weekend here in Ankara / Turkey. I will be working on this conversion only weekends, so this will take some loooong time.. we'll see.. Eren B. |

Posted By: Canada LT28

Date Posted: 12 Dec 10 at 21:05

|

Can you tell how the shift linkage for the tranny looks? Will it be an easy changeover to the stock LT shifter? Also, do you think a 1.9 tdi would also need the sump cut and re-welded? Good work..... Mike |

Posted By: cnycl

Date Posted: 13 Dec 10 at 21:39

|

Hi Mike, Since we're using the original tranny, stock LT shifter configuration will remain intact. So no worries there. Regarding 1.9 tdi sump, Mechano knows it better. He's done a similar engine conversion (2.0l petrol to 1.9 tdi) on his syncro before. But as far as I know/saw desing of the front axle of LT will probably require any other sump to be modified somehow. To keep the engine hump low inside the van, VW engineers stuck everything really close in the engine department. Good luck |

Posted By: Canada LT28

Date Posted: 14 Dec 10 at 00:45

| You are changing out a gasser for the TDI and I think the tranny has the same gear ratios as the diesel LT. Do you know what the difference in RPM is for the two engines. There was a Volvo sitting for a few years behind my shop and just when I was going to ask the owner for it, he towed it away. Gear ratios would have been nice but now I must find something else. Is the top end RPM better on the TDI over the 6 pot? |

Posted By: cnycl

Date Posted: 14 Dec 10 at 07:44

|

Gear ratios of the current gearbox will not probably match TDI engine but we swapped wheels and tyres from 14"/195-80 to 16"/205-80 and this may help a little bit.

In the long run I think it's better to use a different rear axle than playing with the gear box. Especially an axle with a diff lock.

Calculations for rear axles with different ratios and wheel sizes are given below (these are 5th gear calculations).

If you're staying in 100-120 km/h band at 3000 rpm in 5th gear, TDI engine has more than enough pull to handle other gears and long distance rides will probably be much more comfortable.

BTW your stock axle gear ratio may not be 40:9 and transmission ratios may differ please take this into account when making modifications.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Posted By: Canada LT28

Date Posted: 14 Dec 10 at 11:27

Pretty informative . I understand the stock numbers but is the "Dana" from a TDI truck? I am pretty sure I have the stock ratios with the 40:1 diff as I need a strong tailwind and a good down hill to get past 110km/h. I did change to 175/16 wheels (thread somewhere on here) which dropped the rpm a bit but it's not a huge improvement. . I understand the stock numbers but is the "Dana" from a TDI truck? I am pretty sure I have the stock ratios with the 40:1 diff as I need a strong tailwind and a good down hill to get past 110km/h. I did change to 175/16 wheels (thread somewhere on here) which dropped the rpm a bit but it's not a huge improvement. If it is available I may ship one over, or am I nuts  . . |

Posted By: cnycl

Date Posted: 14 Dec 10 at 13:04

|

Dana axle is not from a TDI engine.

They're stock axles of most U.S. branded 4x4's, pick up trucks etc.

We're planning to get a set from the breakers to convert 4x2 LT into 4x4 but thats another story.

|

Posted By: mechano

Date Posted: 17 Dec 10 at 08:49

|

Hi, I guess you need to use an LT sump and cut-weld like I did as any other sump will hit the front-end. For a 1,9 swap you need use an adapter plate between the engine and tranny as the 1,9 4cyl bolt pattern is not the same as the 5 or 6cyl ones. When you use an adapter plate the engine will move forward which may cause even the LT sump to hit the front end, have to check. Eren B.

|

Posted By: Canada LT28

Date Posted: 22 Dec 10 at 11:04

|

Thanks Eren, Have you already put a 1.9 in an LT? I won't get to this before summer but it is always good to know what i am up against. Keep up the good work....  Mike |

Posted By: mechano

Date Posted: 22 Dec 10 at 11:25

|

Hi, No. I did convert my T3 syncro from wasser-boxer to 16 valve petrol and then to 1,9 TDI which also involved to build an adapter-plate and flywheel to covert boxer bolt pattern to inline 4. Definitely a 5cyl Diesel conversion for LT is easier than a 4cyl, as you won't need an adapter-plate. Thanks. Eren B.

|

Posted By: mechano

Date Posted: 16 Jan 11 at 21:16

|

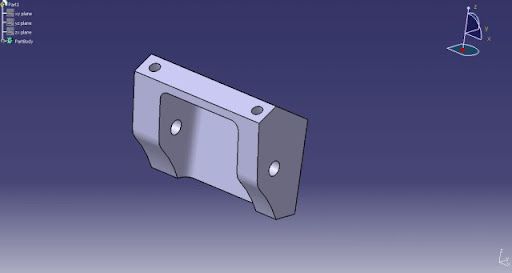

Hi All, It's been a while, it was Christmas holiday, also I was busy at work (moved to another office etc.) Anyway, this weekend I checked engine mounts, I decided to use and modify the LT aluminium mounts. On either side only one hole location is same on TDI engine as the petrol. Turbo Side: This is how the 2,5 TDI (AAT code) engine looks like on turbo side This is how the LT petrol engine looks like, same side The LT oil filter adapter has to be used on TDI engine as If you try to use the TDI's original, the filter will simply hit the engine cross member (front-end). This is how it looked like when I have put the LT filter adapter and LT engine mount on TDI engine: I had to remove the turbo oil return pipe as it would hit the filter bracket. I will make a new pipe to oil sump. I had to grind the mount to clear the turbo itself, also as you can see only one bolt is holding the mount on engine, but as this hole is at correct location so the engine mount location is correct here. Here you can see the the area that I have grind to clear the turbo: I decided to use the hole at the left side of the mount seen above as the second bolt location. So as to do it I have cut these parts: and have them welded as my TIG welder is DC and wont weld aluminium: as for the third bolt, I decided to make a steel part that would bolt on the engine itself where the oil return flange was. It has two M8 bolts. I have designed that simple part which would go between the aluminium mount and engine block:  this part will fit here: I decided to have the part laser cut, I have ordered it and will collect it tuesday. For the other side of the engine, again only one bolt is at the same location and can be used. I have grind the mount a little bit to fit it on the TDI engine: Also I had to cut the dipstick tube of the TDI, no problem as the LT dipstick tube is on the oilpan. I will cut an aluminium part and weld it on the mount to use the other near holes for bolting. Here is a sketch: (yellow lines) All photos can be seen here: http://picasaweb.google.com/102202836518903969722 - http://picasaweb.google.com/102202836518903969722 |

Posted By: Alevaro

Date Posted: 20 Jan 11 at 16:45

|

cnycl Excellent work! |

Posted By: cnycl

Date Posted: 22 Jan 11 at 21:35

Thanks but compliments go to Mechano he's the one struggling with TDI engine in freezing cold weather. |

Posted By: mechano

Date Posted: 30 Jan 11 at 19:28

|

A little update: I finished the turbo side engine mount. Here is the steel part I made which goes between the engine block and the aluminium mount: This is how it looks like when the oil filter is in place: Also I started working on the other side, I have cut an 8mm thick Aluminium sheet to weld to mount as I have sketched before: slowly... |

Posted By: GT500

Date Posted: 31 Jan 11 at 01:02

|

Looking very nice! Great help to me.. I think i'm going to get a spare engine from the LT I'm breaking.. need to have mine off the road as little as possible. Stripped the A6 and are slowly going through the rats nest of a wiring loom.. Very boring! ------------- Rob... The only LT on 18" wheels. |

Posted By: Canada LT28

Date Posted: 31 Jan 11 at 12:42

|

Hi Guys, Eren, regarding the 1.9tdi, I will be cutting the prop shaft back to either put in a laycock overdrive (if i can find one at a reasonable cost) or a friend has a BMW 318 tranny that we are looking at putting in. Either way, Can I make the engine placement back far enough to still fit in and also miss the front end? |

Posted By: Alevaro

Date Posted: 09 Feb 11 at 07:43

And where the sound of the new engine?

------------- VW LT-28 1984 Kastenwagen ACT 2.4L http://oldbusclub.ru/viewtopic.php?f=16&t=830 |

Posted By: mechano

Date Posted: 14 Feb 11 at 11:25

|

I checked the engine compartment and the front end (engine carrier) is really in the middle so placing the engine behind it is very hard I guess. do you really have no chance other than the 1,9 Tdi? as you can easily use the stock LT tranny with a 5 or a V6 V8 engine from VW-Audi ...

|

Posted By: mechano

Date Posted: 14 Feb 11 at 11:30

|

Very little update: I have the engine mount welded and test fitted, I need to drill the 4th hole at top and make a spacer to go between the mount and engine As I am working with aluminium I have to have the parts welded to a specialist, this really takes long time to cut grind test than have it welded than come back and see it doesn't fit, grind bend re-weld ..... |

Posted By: Canada LT28

Date Posted: 14 Feb 11 at 12:53

| Audi only started to import TDIs to Canada and USA this year so engines are rare and I think it is only the 2L that is here (so far). VW is the only "car" company that sells a 4 cyn diesel here. Now that smart diesels are gone and MB engines don't have the fuel economy, there is nothing else. |

Posted By: Canada LT28

Date Posted: 14 Feb 11 at 12:55

| I will use the stock tranny an maybe move it back a bit if it helps to get the new engine in. |

Posted By: mechano

Date Posted: 14 Feb 11 at 13:13

|

I guess earlier 5 cyl diesel Audis were imported to Canada in 80s ? but those engines are indirect injection and are no better than the stock LT diesel, those engines can be converted to direct injection (tdi) using a tdi head and pistons, someone in Canada did but long story...

|

Posted By: mechano

Date Posted: 22 Feb 11 at 12:02

|

Hi All, I worked on the engine wiring loom to make it ready for a test-run before I put the engine to LT. Apart from the main relay, glow plug relay and the engine mount control relay, there are two more high current relays in engine wiring that I couldn't figure out. I don't have the factory repair manual so the only wiring diagram I have is the Haynes which is very simple and many details are missing. I guess those relays will not be used and I will remove them. I will also remove the engine mount control relay as I am using the LT engine mounts which are simple rubber parts unlike the A6's electric controlled ones. This is an OBD1 engine so the communication socket is just a wire terminal in the fuse box. So as to scan the engine with Vag-Com with the OBD2 lead that I have, I bought an OBD2 socket from a T4 in junk-yard, and connected it to the "k-line" of the engine wiring. The good news is, with the OBD2 socket I was able to connect to ECU and the Immobilizer control unit with vag-com and see the error codes. I also programmed the ECU for cruise control, as I will install a turn signal stalk from a T3 with cruise (hope the stalk will fit to LT) So the wiring is now ready to test run the engine, we will see... |

Posted By: GT500

Date Posted: 23 Feb 11 at 08:27

|

If you need to know what your extra relays are for post a pic of them and I'll tell you. If I can... Rob ------------- Rob... The only LT on 18" wheels. |

Posted By: mechano

Date Posted: 27 Feb 11 at 19:18

|

The LT transmission has a long input shaft which sticks into the crankshaft so it has a needle bearing in the crankshaft. However the A6 has the needle bearing in the flywheel, I guess the audi tranny has a shorter input shaft. There is a sleeve in the crankshaft of the TDI, I have cut & removed it: and installed a needle bearing which is 24mm outside & 18mm inside diameter: I have shortened (cut & weld) the oil pickup tube of the 6cyl to fit to TDI: |

Posted By: mechano

Date Posted: 27 Feb 11 at 19:42

|

Before installing the oil-pan, I removed the valve cover & cleaned inside, also cleaned the cover. Look at this part, I guess this an example what makes Audi different: After bolting the oil-pan, putting in oil, hooking up the electronics & fuel lines, I removed the glow-plugs and spun the engine with the starter for the oil pressure to build up and to bleed the fuel pump. I checked the system with vag-com & noticed that the speed sensor is not reading while cranking so the management is not sending fuel to injectors (injection quantity was reading 0mg/stroke) obviously I was not able to start the engine, I removed the speed sensor to see If there was anything wrong that I can see, nothing.. It is strange that when I remove the sensor ECU doesn't throw an error code  I also don't have the airflow sensor at the moment as it was damaged in the crashed car, but this should not be a problem to start the engine ? At least I know that it is possible to run the engine in low-performance mode without the flow meter in later TDIs (with new hot wire sensors).

|

Posted By: light

Date Posted: 27 Feb 11 at 21:00

| Immobiliser? |

Posted By: mechano

Date Posted: 27 Feb 11 at 21:09

working, no error codes..

|

Posted By: mechano

Date Posted: 07 Mar 11 at 20:36

|

Ok, I solved it. The engine is running now. The problem was, (it is not actually a problem..) that you have to crank the engine within around 30 seconds after you turn the ignition on. If you don't the ECU cuts the fuel. After turning the ignition on (connecting a wire in this situation) I wasted time connecting the vag-com checking everything and when I tried to start the engine it wouldn't. During the accident of the A6 many wires are damaged: -the engine speed sensor wire G28, -the wire of the knock sensor on the injector G80 -the advance-retard actuator's wire N108 I have repaired the the G28 cable-connector problem and I guess (did not test) the 30 second wait problem is gone, as the ECU will now sense when I am cranking and probably will supply fuel again. Engine is running roughly at idle, with N108 error code which wont clear, this is I guess due to bad wiring (broken connector) again. Also I found-out that this engine would run with or without the airflow meter like later TDIs. I will sort-out the clutch (to use the dual-mass TDI flywheel and pressure plate of TDI) and put the engine in LT than I will finalize the wiring on the bus. here is the youtube link: http://www.youtube.com/watch?v=OCkiIaIvLHE - http://www.youtube.com/watch?v=OCkiIaIvLHE  |

Posted By: mechano

Date Posted: 01 Apr 11 at 12:42

|

Hi All, After replacing timing belts & tensioners & crankshaft seals, I tried mounting the engine to tranny to see how the A6 clutch will be. It simply won't fit, the release bearing support shaft will hit the clutch disc, so I took the bellhousing off and shortened the support shaft. After this I was able to mount the engine and tranny. The clutch lever has now moved 25mm backwards (measured where the cable is attached), so I have to arrange smt. (weld - extend) so the cable will fit. I have put the TDI in: The pump now hits the back-side of the engine bay, but I guess it will clear when I install the tranny as it would tilt the engine to front of the bus a little, we will see. 5 cyl engine is short: |

Posted By: mat_the_cat

Date Posted: 01 Apr 11 at 14:30

Nice bit of work there! Look forwards to completed photos (and maybe a video?) I wonder if you can make a pie warming shelf to occupy all that wasted space in from of the engine?  I can just about squeeze in a sausage roll on top of my coolant tank, nice and warm after a few miles! I can just about squeeze in a sausage roll on top of my coolant tank, nice and warm after a few miles!------------- Mid engined, 6 cylinder, turbocharged 2 seater - it can only be a VW LT! |

Posted By: t'onion

Date Posted: 01 Apr 11 at 15:08

so will you be making up kits for us all to buy or will this be a one off

------------- LT28 Westfalia FloRida, 2.4 diesel miserable fooker |

Posted By: t'onion

Date Posted: 01 Apr 11 at 15:23

|

also have you got a photo of the underside , mainly around the sump area when fitted to the van ------------- LT28 Westfalia FloRida, 2.4 diesel miserable fooker |

Posted By: mechano

Date Posted: 13 Apr 11 at 08:13

|

here it is: |

Posted By: vwjetta

Date Posted: 22 Apr 11 at 12:24

too much skills guys  ------------- 1965 Datsun spl 310 1967 MGB roadster 1979 Dodge Spacevan 1983 french filth LNA 1989 Volvo 760 GLE 1990 Volkswagen Jetta 1990 Nissan Bluebird 1990 Volkswagen LT35 1984 MZ TS125 |

Posted By: mechano

Date Posted: 22 Apr 11 at 12:45

thanks! I have very limited time working on this project.. just made the oil feed pipe of the turbo  |

Posted By: cnycl

Date Posted: 04 May 11 at 18:01

|

Mechano posted TDI in LT video. Here it comes. http://www.youtube.com/watch?v=yYQBKqEAat0 - http://www.youtube.com/watch?v=yYQBKqEAat0

|

Posted By: stonio

Date Posted: 04 May 11 at 19:21

|

Amazing I am in awe I truly am, a 2.5tdi would be sweet unfortunately I have 0.1% of mechanical knowledge. I can do it I just don't know how to yet! ------------- LT31 2.4 Petrol 1984 Camper Conversion - My Obsession |

Posted By: mcbkat

Date Posted: 04 May 11 at 19:39

Nice fit!  But with all that wiring, I'll stick with a 6 cylinder... Stefan ------------- De Vries LT45 4X4, De Vries LT40 4x4 |

Posted By: mcbkat

Date Posted: 04 May 11 at 19:40

|

Or make a 2.5 mTDI

------------- De Vries LT45 4X4, De Vries LT40 4x4 |

Posted By: mechano

Date Posted: 05 May 11 at 10:12

|

Hi All, Here are the updates: 2 weeks ago with the help of Can (cnycl) we put the transmission back in. I had to modify the clutch cable because the clutch lever is 1 inch backwards now as the dimensions of the dual mass flywheel is different as I described before. So I have cut the original cable and I have put a beetle clutch cable into the LT cable sleeve. The beetle clutch cable is very long, I have cut it to the length I needed than I made a ball with a hole at the centre on the lathe and have it welded on the cable. The new ball on the clutch cable is placed 1 inch far.  Last weekend I started working on the exhaust. I have drawn the exhaust flange for the turbo and have it laser cut, I bought some stainless steel bellows and a vibration absorption flex pipe. Cutting welding next ....    After this, I have run the engine with the electronics laying around as seen in the video to hear the exhaust and test the clutch, all went OK and the sound of the 5cyl TDI is sweet

|

Posted By: mechano

Date Posted: 09 May 11 at 14:48

|

Little update: I just made the turbo oil return pipe, I also have the power steering hoses lengthened as the 5cyl engine is shorter..

|

Posted By: mcbkat

Date Posted: 09 May 11 at 16:07

|

Is there a weight difference between 5 and 6 cylinder?

------------- De Vries LT45 4X4, De Vries LT40 4x4 |

Posted By: readie

Date Posted: 12 May 11 at 20:37

|

Wow, this is exactly what my problem is! I had a leak coming from my original oil return pipe, and my mechanic had it reconditioned, but it now leaks from the union nearer the turbo side. It's a nightmare to even get to the nuts to tighten them, but I see you have just used a rubber hose with a jubilee! What's happening the other end..how did you secure it? looking forward to hearing from you! andy ------------- 1988 LT35 140K 2.4dt |

Posted By: readie

Date Posted: 12 May 11 at 20:44

|

Ah, I have just seen your pic of the other end of the oil return pipe, but it does not look like my 1988 2.4td! With all the hassle I have had it did occur to me to have a decent rubber hose with jubilee clips like you have but I guess the important thing is the connections both ends. I can definitely do it the turbo end, but I need to think about joining it to the other (your first pic)..mmm ------------- 1988 LT35 140K 2.4dt |

Posted By: mechano

Date Posted: 17 May 11 at 10:10

Hi, I don't know how the original 2.4TD is. The 2.5 TDI had a steel pipe from the turbo to the engine block not to the sump. As I have made a blocking plate on the engine block which also secures the engine mount (can be seen in earlier post, CAD drawing also photo) I had to route the oil return to the sump. I have cut the TDI steel pipe, which is mounted to the turbo with two M6 bolts. I bought suitable unions both for the steel pipe and the sump, and cut the rubber hose for the length I needed. The hose is a high pressure one actually, so I can have the ends pressed and get rid of the jubilees however I don't thing that would be necessary. Eren

|

Posted By: mechano

Date Posted: 17 May 11 at 10:11

possibly, I don't know. Eren

|

Posted By: readie

Date Posted: 17 May 11 at 11:23

|

Hi there - thanks for your reply..in the end I took the pipe off and back to pirtek who reconned it in the first place - they redid it perfectly doing all sorts of wierd and wonderful things with solder and joints - and I was able to get it back on no trouble..and leak-free which is great news! Cheers Andy ------------- 1988 LT35 140K 2.4dt |

Posted By: mechano

Date Posted: 08 Jun 11 at 12:09

|

Hi All,

Here is what I did lately: The ALTERNATOR I was looking for a place to fit the alternator, as I said the original LT location and mount can not be used as the alternator would hit the turbo. However there is no other place possible, this photo shows how the engine looks when the hood is closed.  upper right corner would be used by water hoses. So I decided to use the original location by moving the alternator forward. TDI engine is 9cm shorter than the 6cyl LT engine, so If I lengthen the original mount by 9cm the alternator would be placed where it was on the original LT engine. So I designed this part and have it machined on CNC mill:  And have it welded to the original mount:  To use the alternator at this location, the pulley must also be relocated, so I decided to make a spacer to go between the original LT pulley and the cooling fan which would also be the new pulley for the alternator, this way the cooling fan will be at the original LT location:  I have designed that and have it machined on CNC lathe & mill   So here is how it looks like when all mounted on the engine:  This way the alternator easily clears the turbo and the fan sits in the shroud at its original location. If I didn't use the spacer pulley, it would be necessary to extend the shroud. Now I need to make a custom tensioner for the alternator, that will be something like this:  |

Posted By: Canada LT28

Date Posted: 08 Jun 11 at 19:08

|

Very Cool Mechano, Still not ready to put the 1.9tdi in the truck yet. We will see how it is different from the 2.5 ------------- 94 LT28 Doka 2.4D Slow and built to stay that way 87 T3 soon to be a camper |

Posted By: mechano

Date Posted: 16 Jun 11 at 20:12

Thanks! 1.9 can be harder by the way

|

Posted By: mechano

Date Posted: 16 Jun 11 at 20:26

|

I worked on the intake and pressure hoses of the turbo. The air-filter is very big on the LT, as this bus will not be used as a commercial vehicle any more, I decided to use an open type filter with the flow meter inside the filter housing. With a very simple steel bracket, it was possible to mount the flow meter inside the filter housing:  I have routed the air from the flow-meter to the turbo intake via silicone-rubber hoses & steel adapter pipes.. Also the pressure route from the turbo to the intake is via rubber hoses & steel adapters as seen above. There is no intercooler at the moment, this will be later added by the owner of the LT after I finish the whole conversion.

|

Posted By: mechano

Date Posted: 16 Jun 11 at 20:50

|

Next was the accelerator pedal. The TDI has the "drive by wire" system which is a potentiometer connected to accelerator pedal. To connect the accelerator cable to the potentiometer I pulled a M4 thread to the end of the cable: Than I used this chrome linkage part to connect the cable to the potentiometer's cable which I bought from a pneumatic shop: I decided to use the coil bracket of the LT to mount the potentiometer to the body. As the coil of the petrol engine wont be used any more this is possible. Also the location of the coil looks like a safe and dry place for the potentiometer. This is how the system looks like from the under side: Looking from engine bay upper side: Closer: |

Posted By: mechano

Date Posted: 16 Jun 11 at 20:52

|

Here is an overview of the current stage: |

Posted By: cnycl

Date Posted: 16 Jun 11 at 21:22

|

I think it can only be done better in Hannover by Volkswagen. I'd like to say top work as usual but I know you did not spend so much time on detail in your own syncro tdi conversion. Meco's LT is one lucky LT.

|

Posted By: Canada LT28

Date Posted: 16 Jun 11 at 22:50

|

You and Cyncl have a lot of patience and an eye for good work. I only wish i didn't have to spend so much time working so i could spend it on the truck. How do you think the 1.9tdi will be harder than the 2.5? I will making it an Mtdi so the wiring won't be an issue. We are thinking about using an A4 quattro tranny instead of the the stock one but have not made a final decision yet. ------------- 94 LT28 Doka 2.4D Slow and built to stay that way 87 T3 soon to be a camper |

Posted By: GT500

Date Posted: 19 Jun 11 at 09:42

|

Why didn't you try the fly by wire throttle above the LTs pedal? It fits perfect and gets the stupid long cable away.

------------- Rob... The only LT on 18" wheels. |

Posted By: mechano

Date Posted: 21 Jun 11 at 19:44

Hi, I wanted to keep the original LT pedal. I have shortened the cable 44cm, as it was too long for the location I have chosen for potentiometer. First I tried not to shorten it and made a loop but the pedal was too heavy, but now it is light and precise. Did yo make a drive by wire conversion also?

|

Posted By: mechano

Date Posted: 21 Jun 11 at 20:04

Thank you very much! I think for the 1,9 there will be issues with the oil pan, I am not sure If you can follow the route I did as the bolt pattern of the 4cyl oil pan may differ from 5-6 cyl. If you use a LT tranny, an adapter plate would be necessary for sure, with a quattro tranny you wont need it, but how will you cancel the front wheel drive? Some automatic quattro trannies have a front drive shaft outside the tranny, this may be easier to cancel-remove but all quattro tranies have torsen middle differential, this has to be removed also. If you simply lock the front shaft this will probably kill the torsen diff easily. Some very early quattro tranies have an open middle diff with a locker but I guess these are hard to come by and these are for 5cyl engines. I really wonder what sort of solution you thought about this ? (may be: why cancel front wheel drive, make a 4wd LT with independent fron suspension  ) )For the m-tdi, I personally don't recommend it. I worked on some here before and we were never able to get the performance of the stock electronic TDI engine. I know there are pump specialist who can even get beyond the stock HP and torque figures but again I bet it will never be as smooth and silent like the original electronic engine. All that wiring and electronics are there for a good reason. Any chance you find a V6 TDI engine from a later A6, that will be an option and much more fun  |

Posted By: Canada LT28

Date Posted: 22 Jun 11 at 11:57

|

If there is a V6 TDI it will be from a new Tourag and that will cost a mint. I've got the 1.9 so I will try to make it work. We haven't looked at the tranny options seriously yet as I am still sourcing one at a wrecker and I dont want to put a mortgage on the family dog to get it. ------------- 94 LT28 Doka 2.4D Slow and built to stay that way 87 T3 soon to be a camper |

Posted By: Canada LT28

Date Posted: 22 Jun 11 at 12:53

|

I had thought about doing a 4 wheel drive but i will have to look how to do the front end. Very tempting but I also want to make the plug in hybrid and the front (or rear) outlet might drive a generator.

------------- 94 LT28 Doka 2.4D Slow and built to stay that way 87 T3 soon to be a camper |

Posted By: mat_the_cat

Date Posted: 23 Jun 11 at 09:10

Without a locking centre diff though, the output will just take the easiest path - i.e. if it takes less effort to drive the generator then you'll just sit there spinning the generator and not moving forwards...

------------- Mid engined, 6 cylinder, turbocharged 2 seater - it can only be a VW LT! |

Posted By: Canada LT28

Date Posted: 23 Jun 11 at 11:04

|

I guess I will have to look for one with a locking diff. Any idea which years that would be and i suppose it could be from a gasser as I was told the ratio are similar or the same. If it wern't for the current gear ratios, which are suitable for city driving, I would stick with the stock tranny, put a generator on the alternator belt and be done with it. I bought the engine without the wiring and I've shipped over a landy 200tdi pump so the Mtdi, with all its faults will have to do. ------------- 94 LT28 Doka 2.4D Slow and built to stay that way 87 T3 soon to be a camper |

Posted By: Rocky332

Date Posted: 06 Jul 11 at 14:18

|

Hello, My LT: http://www.youtube.com/watch?v=s5CRkvxUyt0" rel="nofollow - http://www.youtube.com/watch?v=s5CRkvxUyt0 Gruß Bernd aus Germany |

Posted By: mechano

Date Posted: 06 Jul 11 at 14:28

wow, you are the first one I've seen who made the same conversion, great!

|

Posted By: Rocky332

Date Posted: 06 Jul 11 at 18:14

Yes i can not so good speak English, better Gernan. I planned the project in November 2010 and it was started 8 weeks. But I have found this site 6 weeks already, thank you for your tips. 2 things I have done differently, I've installed the gas pedal completely. And the alternator has remained at the original location. I used a Volvo 2.5 TDI exhaust manifold. Since the turbo sits in the back. I send you, or you some pictures. Excuse my bad English, I work with the Google translator. With kind regards Bernd |

Posted By: mcbkat

Date Posted: 06 Jul 11 at 18:46

Hallo LT-Freund  . .Pictures please! (Bilder bitte!) Stefan ------------- De Vries LT45 4X4, De Vries LT40 4x4 |

Posted By: Rocky332

Date Posted: 06 Jul 11 at 19:05

Hello, Once I have more time I set the pictures. greeting Bernd |

Posted By: mechano

Date Posted: 07 Jul 11 at 10:52

|

Hi All, I worked on the tachometer here are the details. This LT didn't have a tachometer (rev-counter) before. The owner purchased a tacho from a Diesel LT, the diesel tacho uses the signal from the W terminal of the alternator, however in a TDI car the tacho receives a signal from the ECU. To have the tacho working accurately I decided to use the signal from the ECU. I knew that connecting the tacho simply directly to this signal won't work as there are filters inside the tacho to eliminate the spikes of the signal from the alternator (or distributor). ECU provides a 12V square signal which is well within the limits of the SAK 215 chip used in the tacho. The filters lower the signal so the chip wont sense it so I removed the filters which is a capacitor and a resistor to ground and a series resistor to signal. (the blue circles I draw on the tacho circuit) Here are the pictures of the capacitor and the resistor removed and a jumper is made.   I have tested the tacho, it was working but reading very low like 1/6 th. After examining the circuit, I noticed the capacitor (red circle in diagram) is 0.047 microfarad which is very lower than the one given in SAK 215 data sheet. Asking an electronics engineer friend, he advised to change it, I tried a 0,47 and saw that it reads high enough. the ECU provides the signal at 41,6Hz @ 1000 rpm so I have adjusted the tacho using the trim-pot in it with the help of the signal generator . It now reads accurate.  |

Posted By: mechano

Date Posted: 12 Jul 11 at 11:47

|

Testing the tacho: http://www.youtube.com/watch?v=TvhIFLmJN_I" rel="nofollow - http://www.youtube.com/watch?v=TvhIFLmJN_I one of the lifters is noisy, which disappeared later

|

Posted By: mat_the_cat

Date Posted: 13 Jul 11 at 10:11

|

Is there no end to your talents? Mechanics, electronics, what next?! Tachos are pretty rare over here, out of all the LTs I've seen I've never seen one with a tacho fitted. Mine has one now but I had to buy it new from VW as I couldn't find a second hand one! ------------- Mid engined, 6 cylinder, turbocharged 2 seater - it can only be a VW LT! |

Posted By: Canada LT28

Date Posted: 13 Jul 11 at 10:53

|

There are lots of aftermarket tachs out there but I guess most people want it to look as original as possible.

------------- 94 LT28 Doka 2.4D Slow and built to stay that way 87 T3 soon to be a camper |

Posted By: Canada LT28

Date Posted: 13 Jul 11 at 10:54

What did they charge for it? ------------- 94 LT28 Doka 2.4D Slow and built to stay that way 87 T3 soon to be a camper |

Posted By: mat_the_cat

Date Posted: 14 Jul 11 at 09:50

Too much! I think it was about £250... ------------- Mid engined, 6 cylinder, turbocharged 2 seater - it can only be a VW LT! |

Posted By: Canada LT28

Date Posted: 14 Jul 11 at 11:23

|

Ouch and that probably wasn't the whole cluster.

------------- 94 LT28 Doka 2.4D Slow and built to stay that way 87 T3 soon to be a camper |

Posted By: mat_the_cat

Date Posted: 14 Jul 11 at 11:54

Sadly no, this is all I got: I had some unexpected money, so I casually enquired about availability. Once I found they were still available I just couldn't stop myself!  ------------- Mid engined, 6 cylinder, turbocharged 2 seater - it can only be a VW LT! |

Posted By: Canada LT28

Date Posted: 14 Jul 11 at 11:57

|

I'd like one too but I cannot see paying what would end up as $400

------------- 94 LT28 Doka 2.4D Slow and built to stay that way 87 T3 soon to be a camper |

Posted By: mechano

Date Posted: 14 Jul 11 at 12:11

Thanks for your comments, I am a mechanical engineer working for defence industry in Turkey. VWs are my hobby ever since. |

Posted By: cnycl

Date Posted: 14 Jul 11 at 15:08

I bought the tacho mentioned here from a brick-yard member. As I recall it was around 50 gbps. Also I got the petrol engine tachometer (NOS) from a member and I paid 40 gbps.

Just search carefully (especially ebay.de), you'll find one with a reasonable price in the end.

|

Posted By: mechano

Date Posted: 15 Jul 11 at 14:02

|

Hi All, The wiring is finished and I am testing the bus since Monday. The ECU - immobilizer and the relays are under the seat:  The boost & EGR valves and the MAP sensor are placed behind the manifold: I have also installed the brake and the clutch switches: they are not seen when the plastic cover of the column is attached. The Bus was driving well but it was giving the "start of injection control difference" and "implausible brake paddle signal". I have altered the injection timing many times but couldn't solve it so I have visited the "Bosch diesel service" and have the advance actuator in the pump changed. Guess what the error code is still there! I gave up and started looking for the cause of the "implausible brake paddle signal" I knew that two brake switches has to set perfectly synchronized, I did it but no help  Than I found out that there is no +12V at pedal switches .. It turned out that the fuse at the power line to switches are blown! and that fuse also feeds power to advance valve !!!!! So I replaced the fuse and set the timing again and the bus is even better pulling than before! It is so funny that I never checked the fuse before, It must have blown when the A6 had the accident as the wiring of the advance was cut and probably short circuited. The latest view of the engine bay: |

Posted By: t'onion

Date Posted: 15 Jul 11 at 15:12

well done that man well done that man

------------- LT28 Westfalia FloRida, 2.4 diesel miserable fooker |

Posted By: Canada LT28

Date Posted: 15 Jul 11 at 23:22

The truck is a bit too clean. If I could use it for a while I could make it proper tradesman dirty. Very nice job despite the fuse (we all do that sometimes). ------------- 94 LT28 Doka 2.4D Slow and built to stay that way 87 T3 soon to be a camper |

Posted By: The Weasle

Date Posted: 22 Jul 11 at 14:07

|

Thats absolutely awesome!!! ------------- Super Bus!!! '91 LT35 Carb! Super Golf!! '83 MK1 Golf GTi Cab Super Caddy!! Beluga Blue 2011 Maxi! |

Posted By: T3ADICT

Date Posted: 29 Jul 11 at 02:09

|

wow.. thats a wicked job, so nice to see an lt getting the same kind of love as alot of t3's do engine wise.

i bet its still not super quick as the lt is even more square than the t3.....

plus the extra power potental from these engines is great, if he needs more power you can tune them. ------------- WHY T3's.... because they are just so adictive, and having one just aint enough |

Posted By: mechano

Date Posted: 03 Aug 11 at 15:54

|

Hi All, Two weeks ago me & Mecit (the owner of the LT) made a 650km trip with LT to the west coast of Turkey to see how it performs and test it, (a small holiday). The engine pulls really strong and you nearly never ever need to down shift when overtaking or going uphill. Fuel economy was also very good as the average was 10.2 Liters/100km. Down side is the gearing with 3000rpm@90 km/h (GPS speed), ratios are too short. Mecit (the owner) drove it to Istanbul and I came back to Ankara, he is now working on the "rear-axle conversion" he will be using a US Dana60 rear axle with 3.54 final ratio. A special adapter flange to use LT wheels (actually he is running 16" TATA wheels but they are LT PCD) on the Dana axle will be designed by me. Thanks for reading!  Left to rigt: Me (Eren) & Mecit Ps: all conversion Photos can be seen here: https://picasaweb.google.com/102202836518903969722/LTTDIAATConversionPhotos#" rel="nofollow - https://picasaweb.google.com/102202836518903969722/LTTDIAATConversionPhotos#

|

Posted By: Rocky332

Date Posted: 04 Aug 11 at 13:07

|

Hello, Here my Picture from the conversion, Greats Bernd. http://h1905000.stratoserver.net" rel="nofollow - http://h1905000.stratoserver.net http://www.vw-lt-karmann.de" rel="nofollow - http://www.vw-lt-karmann.de |

Posted By: Alevaro

Date Posted: 29 Mar 12 at 23:37

A wheel dics may fit from any Ford Transit 15-16". It have dimension 5/160 too. High protector may be solve your problem. ------------- VW LT-28 1984 Kastenwagen ACT 2.4L http://oldbusclub.ru/viewtopic.php?f=16&t=830 |

Posted By: wildrovers

Date Posted: 23 Oct 12 at 21:14

|

If I drive to Turkey...please will you do mine ?

------------- Used to be Splits, then Bays, then T3 WBs. Next came Landys, now Mitsu L400 & seeking LT4x4... |

Posted By: kojl

Date Posted: 27 Mar 13 at 19:18

|

I have a diesel rev counter from a car with ECU, is it possible to run it from W terminal signal? ------------- '89 VW T3 bus JX to AAZ |

Posted By: mr sly

Date Posted: 01 Apr 13 at 17:31

| hi saw your post and wondered if you have a use for the distributor that is if its for the thraight six 2.4 engine and is not too worn out |

Posted By: Buss Marius

Date Posted: 23 Aug 18 at 16:13

|

I bought a cambelt set to change on my DW engine, but before i came around to change it, the clutch got stuck. I was able to drive it the 350km home on shitty Norwegian roads crossing 4 smal Mountains With a lot of zig-zag roads. Not easy when you have to stand stil and the engine of to change gear. We then desided to search for a AAT engine (5 pot 2,5TDI 116hp) to fit in the Camper. 75hp in a 3,2 tonn Karmann camper is not enough in 2018. 3 Days after i started to search i found one in Bergen on the west coast. It has only done 235k km and the seller is the grandson of the first owner. On thursday august 30 i'l fly to Bergen to pick it up and drive it the 480km home. The next day the MOT expires, so il have to deliver the License plates. When i deliver the wreck at an autorised junckyard i'l get 3000nok back, and i'l pay 5000nok (450£) for the car, so i am realy happy about it. If i then sel the gearbox for 2000nok and the calippers for 1000 i'l end up geting my transportations costs coverd as well. Now i Wonder, has any one else done a 2,5TDI conwersion to their LT? This guy http://www.vw-lt-karmann.de/html/umbau_auf_2-5_tdi.html" rel="nofollow - http://www.vw-lt-karmann.de/html/umbau_auf_2-5_tdi.html used an exhaust manifold from a Volvo, witch should i use? Audi or volvo? ------------- 87 Karmann LT L 2,4D. 89 T3 Syncro Reimo 1,9TD. 2000 T4 Caravelle TDI |

Canada LT28 wrote:

Canada LT28 wrote: