|

|

Water Pump Leak? Cam belts n all...??? |

Post Reply

|

Page 12> |

| Author | |||||

Junk

Groupie

Joined: 26 Apr 18 Status: Offline Points: 70 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: Water Pump Leak? Cam belts n all...??? Topic: Water Pump Leak? Cam belts n all...???Posted: 02 Apr 22 at 11:23 |

||||

|

anyway thanks a lot monster LT for your posts coz it's that which helped me figure out what was going on with the pump I had ordered.

Moral of the story is that a lot of parts suppliers incorrectly list 20 tooth water pumps as a part for the ACL engine but don't believe what they say, find an 18-toother!

|

|||||

|

LT 35 TD from 1995 (ACL engine) with a box truck body

|

|||||

|

|||||

Junk

Groupie

Joined: 26 Apr 18 Status: Offline Points: 70 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 02 Apr 22 at 11:18 Posted: 02 Apr 22 at 11:18 |

||||

|

hey monster LT.

Its a couple of years ago now and I don't remember at what point in my long cambelt story I took that photo. In the end it went like this: -first paid a mechanic to change belts and pump -fuel pump belt broke unexpectedly and the front end (around the cambelt) was making a horrible noise like a broken bearing when the engine was warm -i decided that the mechanic I'd gone to had obviously scammed me but I was already out of the country, so I changed the cambelt and tensioners with a friend. The horrible noise went away so I assume it was the bearing from the tensioner. -six months later I noticed the cut in the cambelt which I posted a photo of. When I turned the engine it made a horrible squeaking noise which a friend reconed was a broken water pump. (I think this is when I took that photo) -we changed the cambelt and tensioners again, and this time the waterpump too. When we took it out it had the original 95 stamp on it, so the mechanic I had paid in the beginning of the story had obviously either not changed it or changed it for something from a scrappy. -we ordered a new water pump and got sent one with the adjustable positioner bolt and a different number of teeth (which we've been debating earlier in this post) and we fitted it -after reading your posts and losing some sleep I ordered another new water pump, to match the original, with correct number of teeth, and fitted it. And since then I had no problems. So in the end my cambelt came off and went back on again about four times in a year but at least we finally got it sorted.

|

|||||

|

LT 35 TD from 1995 (ACL engine) with a box truck body

|

|||||

|

|||||

Monster LT

Yardie

Joined: 02 Jan 15 Status: Offline Points: 392 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 21 Jan 22 at 23:04 Posted: 21 Jan 22 at 23:04 |

||||

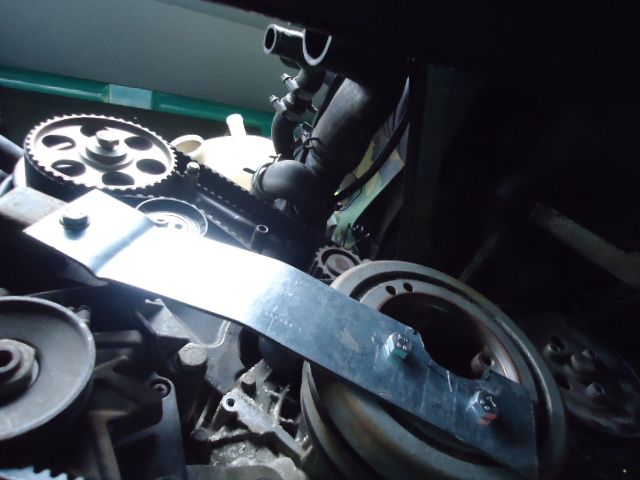

Old thread revival BUT I think I've spotted a problem here that might

be the root cause. Junk, the bottom of this photo shows the water

pump sprocket. I'm pretty sure you've got the wrong water pump fitted!

Looks like you've got the earlier water pump. If your engine is an ACL

then it should be the same as the one in my photos. Notice the different

sprocket? The old water pump position is adjustable to alter cam belt

tension. The ACL's is not. It's position is fixed and the cam belts

tension is determined with the tensioner pulley.

Edited by Monster LT - 21 Jan 22 at 23:05 |

|||||

|

LT45-TD-ACL-intercooler-4x4-1993

|

|||||

|

|||||

Monster LT

Yardie

Joined: 02 Jan 15 Status: Offline Points: 392 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 21 Jan 22 at 22:58 Posted: 21 Jan 22 at 22:58 |

||||

|

Old thread revival BUT I think I've spotted a problem here that might be the root cause. Junk, the bottom of your last photo shows the water pump sprocket. I'm pretty sure you've got the wrong water pump fitted! Looks like you've got the earlier water pump. If your engine is an ACL then it should be the same as the one in my photos. Notice the different sprocket? The old water pump position is adjustable to alter cam belt tension. The ACL's is not. It's position is fixed and the cam belts tension is determined with the tensioner pulley.

Edited by Monster LT - 21 Jan 22 at 23:03 |

|||||

|

LT45-TD-ACL-intercooler-4x4-1993

|

|||||

|

|||||

Monster LT

Yardie

Joined: 02 Jan 15 Status: Offline Points: 392 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 09 Jan 20 at 15:52 Posted: 09 Jan 20 at 15:52 |

||||

|

Just to clarify in hindsight... Messing with the size of belts was unnecessary and a mistake. I was having difficulty getting the recommended belt to fit so got one a little bit longer. The problem lied in the way the alt was positioned. Somehow it wasn't perfectly positioned and the alt being taken on and off revealed that later. Point is, if the OEM part doesn't fit then you need to check why. The longer belt was a short-term solution however underlying issue should have been resolved at the time. Edited by Monster LT - 09 Jan 20 at 16:00 |

|||||

|

LT45-TD-ACL-intercooler-4x4-1993

|

|||||

|

|||||

Monster LT

Yardie

Joined: 02 Jan 15 Status: Offline Points: 392 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 09 Jan 20 at 15:47 Posted: 09 Jan 20 at 15:47 |

||||

|

Just to push my point about the ACL having an 18 tooth pump, here's a link to a part that lists the pump for engine code ACL - btw this is the same group I bought the 20 tooth pump from and at that time they didn't list an 18 tooth pump. When I complained it was wrong their tech people didn't have a clue about this error.

|

|||||

|

LT45-TD-ACL-intercooler-4x4-1993

|

|||||

|

|||||

Monster LT

Yardie

Joined: 02 Jan 15 Status: Offline Points: 392 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 08 Jan 20 at 21:30 Posted: 08 Jan 20 at 21:30 |

||||

|

I mean the rear crank pulley and the fuel pump pulley. You won't find arrows as it's not directional - the belt I mean. I'd change the pump back to spec and keep an eye on things. Well spotted with that nick. Was only a matter of time before that belt would snap.

|

|||||

|

LT45-TD-ACL-intercooler-4x4-1993

|

|||||

|

|||||

Junk

Groupie

Joined: 26 Apr 18 Status: Offline Points: 70 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 08 Jan 20 at 13:11 Posted: 08 Jan 20 at 13:11 |

||||

|

Took a few photos to illustrate what im explaining:  Thats the breakage point, hard to see in this photo as its just a little crack but when you bent the belt it opens right up. You can see a stripe a few mm wide all along the right side of the belt which is a lighter colour, looks like it was rubbing at some point. Not sure if that and the crack are related but quite possible.  Here you can see what I mean when i say the belt is pretty far over on the engine side. It's always been like that since I have the van. Last summer I tried moving it over to the left a few mm bit by bit with a screwdriver but it found its way back to that side in no time. Still, no contact as far as i can see. The part of the back cover which I said was all bent out of place is just under the clip in this photo. As you can see, its still far from straight but we bent it back so it stays far away from the belt.  This is where I think it was rubbing. Photo is from the new setup. On the old setup there was contact between the wire and belt. The wire on the new tensioner still has a few mm of give if i get my finger in there are wiggle it, but it never reaches as far as the belt. Should be ok for now.

Na there are no arrows on it, I remember checking it when he told me that. For me it wasn't a proper explanation that the belt was on the wrong way round... so still no idea how the old belt died. Bit confused about which pulleys you mean, I didnt think there are any on the inj. pump belt? Both times i changed it (well, the first time was me watching someone do it) we just loosened the bolt on the crank coming from the camshaft, once the crank's loose the belt comes off. |

|||||

|

|||||

Monster LT

Yardie

Joined: 02 Jan 15 Status: Offline Points: 392 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 07 Jan 20 at 19:38 Posted: 07 Jan 20 at 19:38 |

||||

I don't remember having mm's of play on that spring. It should be tucked away and not be touching anything. If all pulleys are straight on the front the belt shouldn't really move either. The squeeking may have been the water pump. The one I replaced was squeeky like rubber on shiny clean teeth when turned the pulley after it was removed. Couldn't hear it otherwise.

Maybe was bent when mechanic was trying to get out the water pump. Too much bother. Gave up.

If it was something rubbing you'd expect an even rub ware all over the belt not just a nick outof the belt in a specific spot.

1 full turn of flywheel should equal 2 turns at Cam / pump.

I don't think the belt is directional. I can check when I take a look at my spare. It would show on the belt arrows for direction. Having said that I've not replaced pump belt yet as there is very little space to get at the pulleys.

Edited by Monster LT - 07 Jan 20 at 19:42 |

|||||

|

LT45-TD-ACL-intercooler-4x4-1993

|

|||||

|

|||||

Junk

Groupie

Joined: 26 Apr 18 Status: Offline Points: 70 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 07 Jan 20 at 13:45 Posted: 07 Jan 20 at 13:45 |

||||

Havent got a camera handy but its a little nick in the engine side of the belt. It was making a horrible sweak noise when I turned it by hand (not audible when the engine was running) but it was impossible to tell where it was coming from. Changed all the belts, tensioners, water pump and have a few theories of where it was rubbing or why it might not have been straight: -Most likely, the little bit of wire which hooks the tensioner onto the engine was rubbing on the belt (picture below). Looked like it was touching the belt a bit, and would explain the sweaking noise when turning the engine by hand. Problem is, theres a few mm give on that wire even when its put in properly. The new one isnt touching the belt but im worried it might move over again over time, as it's still got give. I'll have to keep checking it.  -The metal plate which sepates the belt from the engine was very bent around the top where it looks like someone levered off the belt with a screwdriver, pushing against it. In a few places was very close to the belt. Bent it back now. -The water pump looked like it didnt enter this world long after I did. Seemed to move normally but such an old water pump definately shouldn't have been in there. -Last year put a new Injection Pump belt without replacing the Timing Belt. Then later changed the tensioner and the idler of the timing belt, again without changing the rest. Few people told me you're supposed to do it all at once. Another thing is, as long as ive had the truck (2 years) the belt's always been pretty far over on the engine side, although I never gave me problems before. Now I put the new one on and did the tensioner with correct torque and its still pretty far over on the engine side, although i cant see or hear anything rubbing.

That's what I thought when I wrote that post but...Afterwards I turned the engine round again and realised that the marks on the Inj. Pump crank and the Flywheel do match up, but only on every seccnd rotation of the Inj. Pump Crank. I can only assume that's how it's supposed to be? Would be a weird coincidence if the pump and the crankshaft ran out of time but matched up exactly every second rotation. Think i was being a bit of an idiot basically.       As you can tell by now, the process of me learning mechanics is a long and slow one.

Literally f*** knows. Just snapped in two while we were driving. Put on a new one and everything went ok with it from then onwards. Took it to a few mechanics and no one could shed any light on the situation, other than maybe it had been somehow put on badly last time. One mechanic told me there is a right way round and a wrong way round to put on the belt... Didnt make much sense to me as the belt is symmetrical but he was certain that was it.

|

|||||

|

|||||

Monster LT

Yardie

Joined: 02 Jan 15 Status: Offline Points: 392 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 09 Dec 19 at 20:19 Posted: 09 Dec 19 at 20:19 |

||||

|

Yeah. Was very simple. Used an allen key to shift the tensioner and undid the nut. You should be able to see any damage to that bolt or the tensioner. Just be careful not to over torque it - 10Nm i think, very low anyway. If you have feked it the you can easily make a new one with an M8 nut + bolt and some thread lock. Reasons your belt may be damaged? Have you checked the cam pully, crank pulley & water pump are rotating true? Is the waterpump moving freely? Have someone turn it over slowly by hand and check. Is every thing clean around the crank pulley? No debris or gunk? It may be as simple as the bottom cover not being fitted back on correctly. It's a bit fiddly and needs to fit under the top cover if memory serves me, so maybe catching the belt a little. Make sure also the water pump and belt are correct. I ended up with the wrong pump, too many teeth / bigger pulley as I posted above). None of the parts sellers would offer the correct pump when I searched by vehicle / reg. I needed to get one for a T4. Have you got some photos of the damage? From your post www.brick-yard.co.uk/forum/timing-marks-not-lined-up_topic94316.html sounds like you skipped some teeth too. Why did the fuelpump belt break in the first place? Edited by Monster LT - 09 Dec 19 at 20:30 |

|||||

|

LT45-TD-ACL-intercooler-4x4-1993

|

|||||

|

|||||

Junk

Groupie

Joined: 26 Apr 18 Status: Offline Points: 70 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 06 Dec 19 at 11:34 Posted: 06 Dec 19 at 11:34 |

||||

Hey Monster LT did you do it with a screwdriver? What was your experience? I changed my timing belt tensioner and pulley 6 months ago and now my belt is way off centre and starting to deteriorate on the cam/crank side... must be rubbing somewhere. I did the job with a mechanic who assured me it was fine to take out the tensioner with a screwdriver. Now I've got to replace the belt & try and work out why it was so off centre. I'm worried that we damaged the thread of the securing screw of the tensioner when we took it out. Only noticed it yesturday so it's still under investigation but would be good to know if you had similar problems. Thanks!

|

|||||

|

|||||

Monster LT

Yardie

Joined: 02 Jan 15 Status: Offline Points: 392 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 20 Jul 16 at 00:16 Posted: 20 Jul 16 at 00:16 |

||||

|

Job done finally and a few more hiccups on the way....

The Febi 22206 water pump I had been sent was the wrong fitment. Didn't spot the difference until I'd already put it on attempting to fit the cam belt which seemed too short to go on even though it was the same spec as the old one... then I thought to check the number off teeth on it;s drive sprocket and realised the new pump had 2 extra teeth! Duh! 20 teeth instead of 18, so I had to disassemble it and find a pump that fitted. At first wasn't easy. Some parts sellers recomended to change cam sprocket! No ef'in way! Other sellers (TPS) were just plain rude to me for asking how many teeth the bloody pump's drive spocket had. VW Vans were no help either as there was no info on teeth for the part they had listed and parts were now obsolete so told me to get aftermarket. Finally had success after calling some friendly local motor factors who managed to find me 18 tooth pumps. After a shop around I got one and it was near exact copy of the original and cheap as chips ( + a large cod).   In the meantime I'd snapped off the M6 thread of the spacer bolt in the head. Easy fix if you have a left hand drill bit of smaller than 6mm diameter... but I didn't, so needed to wait for one to be delivered as they are not easy to come by.... nor is a replacement spacer bolt so needed to improvise. I used some rod connectors threaded onto a M6 screw, ground it down to the length of the original and fitted that until the correct part turns up. I replaced the pain in the ass belts with longer ones and found with the alt belt only 13mm longer still was difficult to get on and I had to adjust it to max to get it tight enough. The PAS belt was really loose going on and adjusted to max to tighten correctly so I'd say a 813mm would've been better than the 825mm I'm using but it works.  So after a few more hrs of work the Monster was back up n running well. In hindsight I think I could've removed the water pump by just removing the cam covers even though working space is compromised, draining the radiator, removing back plate bolts and cam belt tensioner and half removing cam belt, then remove water pump (getting ready for the splash) and bend the backplate enough to wiggle out the old pump and wiggle in the new one, carefully put it all back together and hope for the best. Much quicker - less stress n bullshizzle. Edited by Monster LT - 20 Jul 16 at 00:46 |

|||||

|

LT45-TD-ACL-intercooler-4x4-1993

|

|||||

|

|||||

Monster LT

Yardie

Joined: 02 Jan 15 Status: Offline Points: 392 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 08 Jul 16 at 17:52 Posted: 08 Jul 16 at 17:52 |

||||

|

Thanks LTCamper89.

The original VW ones that came off 10mnths ago were 12.5x800 for the PAS and 10x800 for the Alternator. The ones I had difficulty removing were 13x800 for the PAS and 10x800 for the alt. When I measured old & newer to compare the only difference was the old alt belt was 5mm longer, probably stretched due to age. Anyway I'm planning to cheat from now on... I've ordered a 13x825 for the PAS which was the most difficult to remove and a 10x813 for the Alt. Hopefully these will go on and off much easier. The truck mechanic that put 'em on must've had hands of steel otherwise can't think of why there may be such a difference this time around. The water pump that came off is the original with a '92 stamp on it so never changed and is f'**kd. It's drive sprocket has a rubbery feel and squeaks when turned so I'm guessing the internal o-ring has got out of place and is now stuck. Couldn't tell until the cam belt came off so glad I spotted that little leak. New pump next to old that retired after 23years and less than 30,000kms of service.  Edited by Monster LT - 09 Jan 20 at 15:51 |

|||||

|

LT45-TD-ACL-intercooler-4x4-1993

|

|||||

|

|||||

LTCamper89

Vanorak

Joined: 18 Apr 12 Location: The Toon Status: Offline Points: 4285 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 07 Jul 16 at 20:21 Posted: 07 Jul 16 at 20:21 |

||||

|

Handy Germans

Power steering belts can be different lengths though the alternator belt seems to be 800km. Icky has had the same problem regarding belt length, possibly due to a slightly longer one being fitted previously, and so running out of adjustment. |

|||||

|

1989 LT28 2.4D Saviour of 6Music, well one of them. Now playing http://www.bbc.co.uk/radio/player/bbc_6music

VW LT Camper not Cramper ....at least the roof is not rusting away.... |

|||||

|

|||||

Monster LT

Yardie

Joined: 02 Jan 15 Status: Offline Points: 392 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 06 Jul 16 at 17:26 Posted: 06 Jul 16 at 17:26 |

||||

|

Ah, Thanks AndyT but I meant that a few days ago I was having difficulty turning over the engine by hand to find TDC.

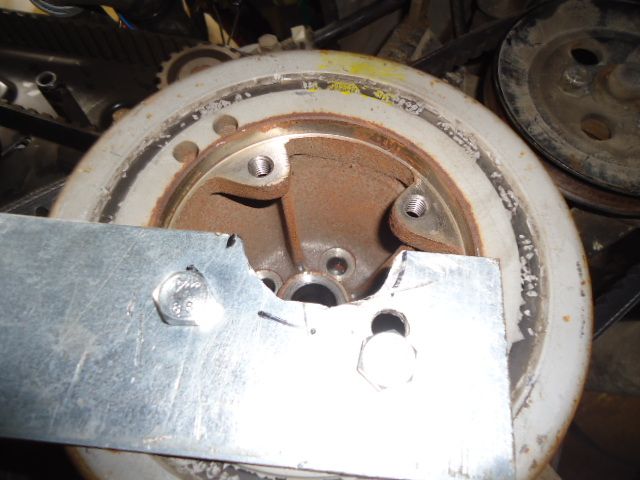

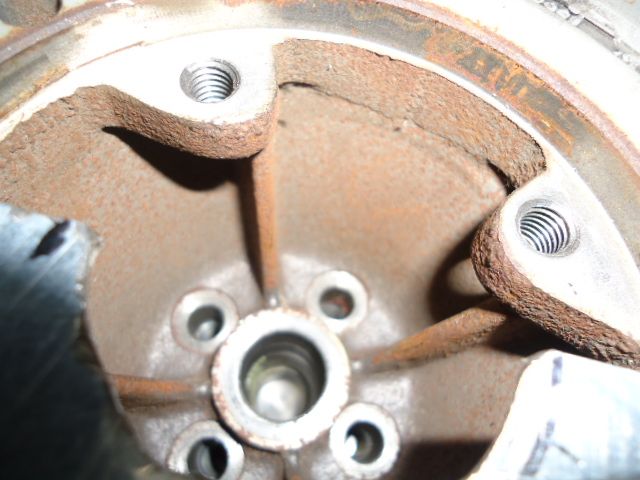

http://www.brick-yard.co.uk/forum/turn-over-by-hand-tdc_topic91707.html It wouldn't budge then so I thought I'd have a go at taking off the big center bolt on the crank pulley since everything seemed solid but when I tried to take the center bolt off the engine began to "turned over" so I made a tool to lock the crank. Here it is attached to the vibration damper:   And here are some after shots...     Actually the "big one" was easy as pie.... never 460Nm. Edited by Monster LT - 06 Jul 16 at 18:49 |

|||||

|

LT45-TD-ACL-intercooler-4x4-1993

|

|||||

|

|||||

AndyT

Moderator Group

Joined: 16 May 08 Location: Ammanford Status: Offline Points: 2274 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 06 Jul 16 at 13:22 Posted: 06 Jul 16 at 13:22 |

||||

|

Haven't got time to search at the moment, but I'm sure someone on the forum has done this with a long bar of some kind.

Try an advanced search for old posts, could save you time and money. Good luck |

|||||

|

LT28 1979 2.0 Pampas Nevada Camper LPG 93K, 1980 T3 A/C Camper 98K,1994 RRC 3.9 LPG 120k , 1998 Audi A6 Est 2.5 V6 diesel 127k

|

|||||

|

|||||

Monster LT

Yardie

Joined: 02 Jan 15 Status: Offline Points: 392 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 06 Jul 16 at 12:22 Posted: 06 Jul 16 at 12:22 |

||||

|

Tried the old belts that we removed 10 months ago for size and the alt belt goes on easy so is a lot looser than the current one I'm struggling to get off still... so I'll probably leave 'em on till the vibration damper comes off.

Tried to remove the center bolt on the vibration damper but the crank n cam started to move! Sods law! Couldn't get it to budge the other day and was hoping to get away without making a locking tool but looks like I'll be having to make one now...  |

|||||

|

LT45-TD-ACL-intercooler-4x4-1993

|

|||||

|

|||||

AndyT

Moderator Group

Joined: 16 May 08 Location: Ammanford Status: Offline Points: 2274 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 06 Jul 16 at 12:19 Posted: 06 Jul 16 at 12:19 |

||||

|

Ok I understand now. (Link to new Manuals done btw)

What you need is the equivalent of a tyre iron, once the belt is started on the edge of the pulley a turn of the crankshaft will roll it off. This is probably how they got it on. Only other options I can think of are:- Remove main bolt on alternator. Cut belt, make sure new is a fraction longer to ease fitting. |

|||||

|

LT28 1979 2.0 Pampas Nevada Camper LPG 93K, 1980 T3 A/C Camper 98K,1994 RRC 3.9 LPG 120k , 1998 Audi A6 Est 2.5 V6 diesel 127k

|

|||||

|

|||||

Monster LT

Yardie

Joined: 02 Jan 15 Status: Offline Points: 392 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 06 Jul 16 at 00:10 Posted: 06 Jul 16 at 00:10 |

||||

|

Hi Andy,

Alternator tension adjusting bolt is adjusted as far as it will go as can be seen in last photo I added. Alternator is now contacting it's bracket above and can't move any further as can be seen in 2nd from last photo I added. Power steering pump is in same situation against it's bracket and adjusting bolts loosened to max. Still not enough slack in either belt to remove normally. Heat is often used to soften rubber to gain a little more stretch from v-belts when fitting. Submerging the belt in hot wtater often does the trick however can't do hot water if belt is on. Heat gun could end up damaging belts and as they are nearly new I want to avoid that. Edited by Monster LT - 06 Jul 16 at 00:15 |

|||||

|

LT45-TD-ACL-intercooler-4x4-1993

|

|||||

|

|||||

Post Reply

|

Page 12> |

| Tweet |

| Forum Jump | Forum Permissions  You cannot post new topics in this forum You cannot reply to topics in this forum You cannot delete your posts in this forum You cannot edit your posts in this forum You cannot create polls in this forum You cannot vote in polls in this forum |